Description

Introduction

Gill oil condition monitoring sensors use powerful magnets combined with inductive technology to monitor the accumulation and type of ferrous debris in oil systems, providing real-time insight into machinery health.

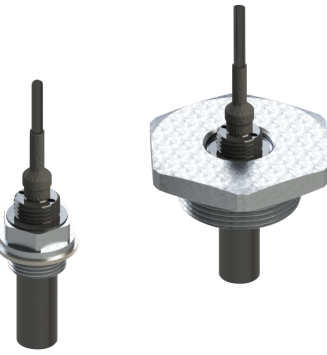

The sensor, which is around the size of a magnetic drain plug, is introduced into the oil flow and uses powerful magnets in its tip to attract and retain any ferrous particles in the oil. An inductive coil within the sensor probe coupled with innovative electronics enables the sensor to differentiate and measure both fine and coarse particles.

The coil alternately generates magnetic pulses and measures the strength of the debris’ induced magnetic field, providing accurate insight into the machinery condition and early warning of component failure.

Three channels

The sensors offer three independent analogue output channels. The first channel measures fine particles in the range of 1-850 µm which are typically caused from wear in engines and gearboxes. This can indicate when the oil needs changing or accelerated wear rates, indicating a potential problem.

Coarse particles are measured on the second channel in a size range of 2-5mm, typical of debris generated by early mechanical failure of bearings or gears in a gearbox, for example.

By also incorporating temperature measurement and dielectric measurement, a third channel gives the additional functions of oil temperature measurement or a change in oil dielectric, which will indicate either water contamination in the oil or loss of oil.

Features & Benefits

- Captures fine wear & coarse failure ferrous particles

- Water in oil contamination detection

- Oil temperature or oil presence measurement

- Reduce unplanned downtime

- In-line electronics

The Gill 4212 Oil Condition Sensor

Fine and coarse particle contamination is a major cause of breakdowns in hydraulic and lubrication oil systems; therefore continuous real-time oil debris monitoring plays a crucial role in developing a predictive maintenance strategy.

The 4212 Oil Condition Sensor offers 4 types of measurement outputs and with no specialist knowledge required to analyse the outputs, the sensor offers a low cost of ownership. It allows the end user to identify and thereby eliminate an unplanned breakdown; the oil condition sensor gives a quick and positive return-on-investment.

17 New thread adapters now available:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Oil Condition Sensor has been developed to assist the plant or automotive engineer to improve the reliability of their equipment. By continuously monitoring the most common causes of gearbox and transmission failure, the sensor provides early indications of a potential problem allowing for planned investigation and remedial action to be implemented before catastrophic failure occurs.

Powerful magnets attract and retain ferrous particles in the fluid. Identification is either fine wear particles signalling fluid cleanliness or increased wear rates, or coarse failure pieces giving early indication of possible component failure.

Additionally, the sensor will provide an alarm condition of water contamination in oil, which can lead to subsequent part failure and an oil presence alarm, signalling either low oil levels or leakage.

Available with either 0-10V, 4-20mA or CAN outputs, along with a local visual alarm option, the sensors are designed to suit most data collection devices such as Dataloggers, PLC’s, ECU’s. The sensor features a simple metric thread with an O-ring seal for direct fitting into a gearbox or transmission housing.